Bottom Bracket Selection Guide

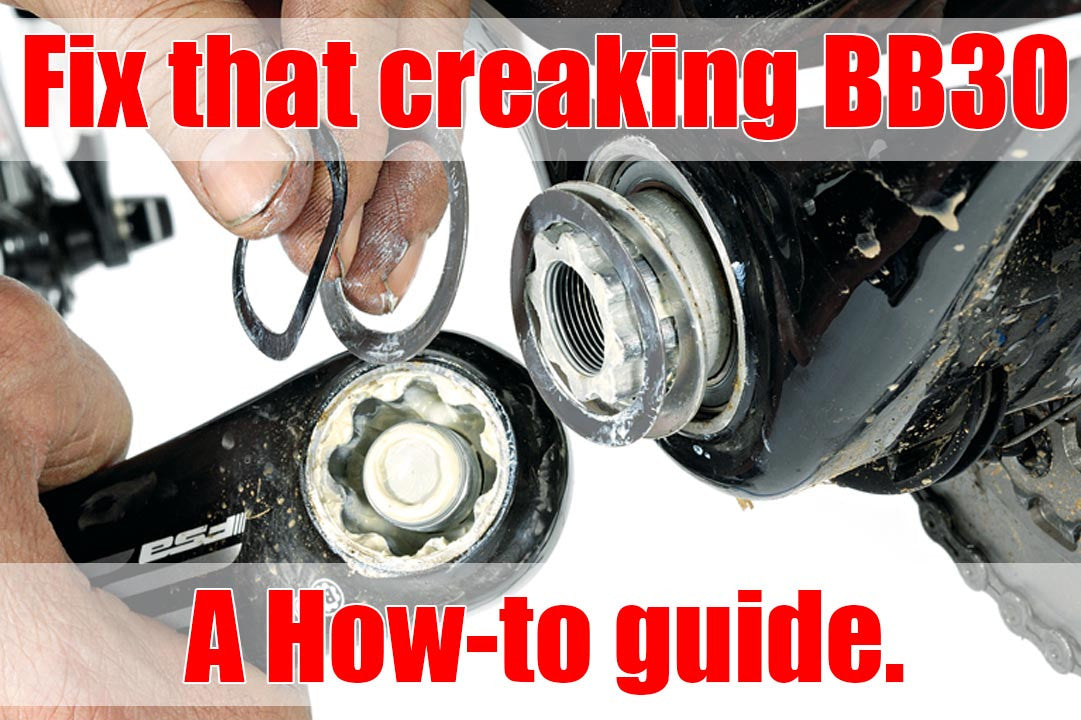

My BB30 bike bottom bracket is creaking. Help!

For the best and simplest solution on how to fix a creaking BB30 bottom bracket, you’ll want to get one of our BB30-30 or BB30A-30 modules that you can just press in, insert the crank, and go ride faster than ever in silence. Check out the video to learn more about our plug-and-play BB30 solutions here.

But if you’ve purchased a set of BB30 (6806) bearings from us to do a traditional BB30 set up in your bike, you will want to ensure the best (read quietest) results. This blog will tell you how.

To clarify, BB30 is not the same as PressFit30. BB30 bottom brackets call for bearings to be pressed directly into 42mm ID interfaces in the frame bottom bracket shell whereas PressFit30 bikes have 46mm ID frame bottom bracket shells and use a housing, often plastic, with a bearing pressed in it to do the job.

We're only talking about BB30 bottom bracket problems in this article.

Most BB30 bikes come with 30mm spindles because that is exactly what the system was designed around, so it "makes sense". BB30 was rolled out by Cannondale years ago in alloy bikes. It's a superb economy of components from a design standpoint: bearings press in a frame, crank slides into bearings, BOOM...done. And then it creaks. You fix it. A few weeks later your bottom bracket is creaking again. And again.

To stop the bottom bracket from creaking, we must understand what is causing your bottom bracket to make noise. So why is your bottom bracket creaking? Answer: movement. A creak, any creak, is movement. The leading cause of BB30 bottom bracket creaking is bearing migration within the frame bb shell during use. The bearings shift around a minute amount, resulting in the dreaded creaking sounds. Typically somebody greases the bearings to fix it. This only masks the problem, or more often, exacerbates the problem. To fix a bike crank creaking noise one must stop these micro-movements.

So here's how we deal with a BB30 bottom bracket making noise when a 30mm spindle is in use:

Remove your BB30 crank, clean it, and put it in the freezer. Trust me, just do it.

Knock those old BB30 (6806) bearings out and throw them away. Now take those brand new Ceramitech or BBInfinite ABEC-7 bearings out of the package and meticulously clean every bit of oil and grease from the outside. Don't mess with the grease inside the bearings. We just want to degrease the outer, flat face that interfaces with the frame bb shell. Now give the frame bb shell the same treatment. Use White Lightning Clean Streak or rubbing alcohol and a clean rag or paper towel. Don't use automotive brake cleaner or carburetor cleaner, for God's sake. You'll strip the finish off your bike. Now, let it all dry. Is it clean? Good. Now soak a q-tip with some Loctite 609 or VibraTite 530 and dab the fluid onto the flat outer surfaces of the bearings. Start the bearings in the frame by hand and...

What, you don't have any Loctite or VibraTite? Just ask us when you order and we'll send some with the bearings.

Now that the bearings are started in the frame by hand, make sure they're nice and square. Next, engage the dies and the press. We recommend our own bike bottom bracket tools for this, but the Wheels Mfg. Large Sealed Bearing Press (Press-1) is good too. Just make sure you use a press that ONLY pushes on the outer race, like ours, or one that presses on both races simultaneously, as does the Wheels Mfg. one. Never, ever press bearings in with a tool that primarily engages the inner race. You will ruin the bearings as quickly as if you had struck them.

Begin driving the bearings inward. This is a critical moment and takes some vigilance if you really want to stop your bottom bracket from making noise. If the bearings go out of square by even the slightest degree, stop, remove the crooked bearing, and reset it squarely before recommencing your press operation. Press the bearings in until they sit firmly against the backstops or snap rings. The thin coat of VibraTite 530 or Loctite will take it from here. Use alcohol or Clean Streak to clean off the residual Loctite. Let the whole thing sit for at least 3 hours if possible.

Install the crank with all hardware as recommended by the manufacturer. Yes, grease the spindle.

Why did we freeze the crank? We advocate this because aluminum shrinks appreciably at moderately cold temperatures. Shrinking the spindle slightly is enough to let it slide in by hand instead of going at it with a mallet. This allows the wave washer to do its job and prevents you from using the crank spindle as a drift to dislodge a bearing you just got done installing with Loctite.

So there you have it, a bottom bracket all done and guaranteed to be creak-free for a good long while. Creaking is never acceptable. Creaking is often misdiagnosed as a bad bottom bracket. If your bike is still creaking check out our "Bike creaking" blog to learn how to silence them today!

OMG. Can’t wait to try this. I practically cry each time I get on my bike.

M

Comments will be approved before showing up.

Juny Binamira

September 30, 2017

This is the BEST article i’ve ever read about BB30 creaking and what to do about them. And a very enjoyable read to boot – whoever writes the Park manuals would learn a thing or two by reading your stuff.